Advances in Material Cost Control Technologies and Tools

In recent years, the manufacturing industry has witnessed remarkable advancements in material cost control technologies. These innovations aim to enhance efficiency, minimize waste, and streamline processes. One of the most significant developments is the integration of sophisticated data analytics tools. Organizations are now leveraging these tools to identify cost-saving opportunities associated with various materials in real-time. With data becoming more accessible, companies can monitor their material usage patterns closely. This is crucial for identifying areas where costs can be reduced. Additionally, advancements in machine learning enable predictive analysis, which forecasts materials requirements based on historical data. This predictive capability prevents excess inventory and aligns procurement strategies, ultimately reducing costs. Smart manufacturing technology has further played a vital role in optimizing material costs. Automation not only enhances production rates but also improves the accuracy of material handling. Companies are now investing in intelligent software that can concurrently assess cost, quality, and supplier reliability. Investing in these technologies sharply reduces material costs while increasing overall efficiency and sustainability. Thus, manufacturers are not just cutting costs but becoming more competitive in an ever-evolving market landscape.

Moreover, implementing cloud-based solutions enhances material cost control practices significantly. These systems allow organizations to access and manage data remotely, promoting real-time collaboration among team members. With cloud storage, stakeholders can share information effortlessly, ensuring everyone is on the same page regarding material needs and costs. In addition, cloud solutions provide a centralized system that integrates data from various departments such as production, purchasing, and inventory management. By having real-time visibility into material costs, organizations can quickly respond to fluctuations and adapt strategies accordingly. Furthermore, advanced reporting features enable businesses to analyze trends and make informed decisions. Companies can identify high-cost materials and seek alternatives or negotiate better pricing with suppliers. Additionally, integrating ERP (Enterprise Resource Planning) systems is essential in maintaining a seamless flow of information regarding material costs. This integration improves overall operational efficiency and encourages a proactive approach to cost control. Adopting technology not only promotes sustainable practices, reducing material wastage but also optimizes the supply chain. As a result, manufacturers can gain a competitive edge while maintaining profitability in a demanding market.

Importance of Automation in Material Costing

Automation is revolutionizing material costing and control by simplifying data collection and analysis processes. With automated systems, companies can track material usage accurately without manual intervention, minimizing human error. Real-time monitoring systems allow businesses to receive alerts when material levels drop or reach critical thresholds, enabling timely restocking and preventing production delays. Furthermore, advanced technologies facilitate accurate forecasting of material needs based on demand fluctuations. This aspect of automation not only improves operational efficiency but also eliminates unnecessary expenses related to overstocking or stockouts. Implementing automated tracking systems also provides comprehensive data analytics. Businesses can analyze the efficiency of resources versus their costs, allowing them to adjust processes for optimal savings. Additionally, automation supports lean manufacturing principles by promoting just-in-time procurement strategies. These strategies minimize holding costs and ensure that materials arrive precisely when needed, enhancing overall productivity. The integration of automation within material costing is an investment that enhances decision-making components and drives profitability. Consequently, organizations adopting such technologies can position themselves well within competitive markets while ensuring sustainability and reduced environmental impact.

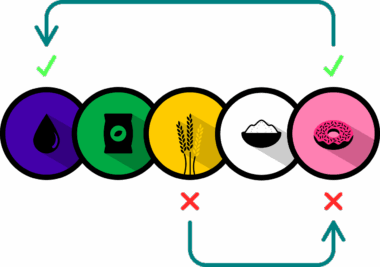

Furthermore, intelligent procurement systems have emerged as crucial tools for optimizing material costs. These systems utilize advanced algorithms to analyze supplier performance and pricing structures effectively. By automating the supplier selection process, companies can pinpoint the most cost-effective options while maintaining quality standards. Additionally, intelligent procurement tools facilitate negotiations, leveraging historical data to secure better terms and prices. This analysis ensures organizations are not only paying the best prices but also building long-term relationships with reliable suppliers. Moreover, data analytics within procurement helps identify trends in market pricing for materials, allowing companies to strategize purchasing decisions proactively. It enables businesses to take advantage of price fluctuations, securing lower prices during market dips. This adaptability in procurement strategies significantly reduces material costs across the board. Furthermore, supplier integration enhances transparency throughout the supply chain, allowing companies to track material flow better and ensuring accountability. As organizations embrace intelligent procurement systems, they experience improved cost efficiency without compromising quality, leading to enhanced overall competitiveness in the marketplace while driving innovation and sustainability.

Role of Sustainability in Material Cost Control

Sustainability practices play an increasingly vital role in material cost control, aligning environmental responsibility with economic efficiency. Companies are now recognizing that sustainable practices often lead to operational savings and reduced material waste. Implementing eco-friendly materials can generate cost benefits over time, particularly as consumers gravitate towards environmentally responsible brands. By utilizing recycled or renewable materials, businesses not only reduce their environmental footprint but also lower raw material costs. Additionally, optimizing production processes to minimize waste is essential; this includes reducing scrap and improving yield rates. Sustainable models enable more efficient energy use during the production process, which directly correlates to reduced operational costs. Moreover, organizations are promoting collaboration with suppliers who share their sustainability values. Engaging in sustainable sourcing can often lead to discounted rates while enhancing corporate reputation. Consumers increasingly prioritize sustainability, leading companies to reevaluate their strategies. Companies focused on reducing their environmental impact tend to attract more customers and enhance brand loyalty. Ultimately, integrating sustainability into material cost control strategies significantly strengthens a business’s position in the market, driving innovation that benefits both the environment and profitability.

In addition, training and development of personnel in material cost management technologies are paramount. As these technologies advance, the workforce must also evolve through the acquisition of appropriate skills. Companies should invest in ongoing training programs that emphasize the utilization of new systems and technologies. These programs not only enhance employees’ expertise but also improve the way material costs are managed across the board. Furthermore, creating a culture of continuous improvement ensures that personnel are engaged and motivated to explore new cost-saving opportunities. This cultural shift can lead to collaborative efforts between departments. Encouraging teamwork can result in innovative solutions for managing material costs effectively. Regular workshops and seminars can be beneficial for keeping employees updated with industry trends and technological advancements. Moreover, organizations that prioritize employee training often observe lower turnover rates and increased job satisfaction. Investing in human capital ultimately translates to improved efficiency in material control processes. Therefore, by emphasizing training and development, businesses can strengthen their material cost control strategies, leading to enhanced profitability, productivity, and sustainability.

Future Trends in Material Cost Control

Looking ahead, the future of material cost control lies in the integration of advanced technologies, shaping the landscape significantly. One such trend is the growing application of artificial intelligence and machine learning in analyzing material costs. These technologies are anticipated to provide predictive insights that can drastically improve procurement strategies and resource allocation. Additionally, the use of blockchain for supply chain transparency is expected to emerge as a key player, enhancing trust between manufacturers and suppliers. Organizations may also increasingly adopt IoT (Internet of Things) devices for real-time tracking and monitoring of materials. Such innovations create opportunities for unprecedented visibility into supply chains, reducing potential disruptions and enhancing efficiency. Furthermore, as regulations on sustainability tighten, businesses will need to adopt more eco-centric approaches in cost control practices. This shift will demand innovative materials to replace traditional ones, ensuring compliance while also appealing to environmentally-conscious consumers. In summation, businesses that stay ahead of these trends will likely enhance their competitive edge in material cost management. Acceptance of these advancements promises to create significant efficiencies, reduce material costs, and foster sustainability across industries.

In conclusion, embracing advances in material cost control technologies is critical for manufacturers aiming to remain competitive in a continuously evolving market. These advancements—ranging from automation in procurement to sustainability practices—offer tremendous potential for cost savings. By integrating modern technologies such as data analytics and AI, businesses can make informed decisions based on real-time data and trends. Moreover, fostering a culture of training and development within organizations serves to maximize the benefits of these technologies. As market dynamics shift and sustainability becomes paramount, the adoption of more advanced material cost management strategies becomes essential for future growth. Moving forward, organizations must put in place actionable strategies that align with technological advances and customer demands. Companies adopting these innovations can reduce waste, improve profitability, and drive customer satisfaction. The synergistic effect of enhanced technology and workforce skill sets undoubtedly propels businesses toward a prosperous future. Ultimately, the future of material cost control lays in the hands of innovators and forward-thinking organizations willing to embrace change and adapt to an ever-changing global landscape.