The Effect of Supply Chain Disruptions on Material Costs

Supply chain disruptions have greatly impacted material costs in various industries. These disruptions can occur due to natural disasters, political unrest, or even global pandemics. The complexity of modern supply chains means that a problem in one area can cascade through many others. Companies must understand the direct relationship between supply chain stability and material costing. When disruptions occur, sourcing materials becomes more challenging, which can lead to price increases. Furthermore, suppliers may have to raise their prices to cover increased operational costs, leading to higher material prices for manufacturers. This creates a ripple effect throughout the supply chain. For instance, when a major supplier raises prices, downstream effects reach retailers, which further pressures consumers. Businesses need to develop contingency plans and strategies to mitigate the impact of supply chain issues. Quite often, the ability to maintain a constant supply at a stable cost depends on effective risk management. This ensures that companies can continue their operations without significant interruptions and absorb price shocks when they occur. Innovations in logistics and inventory control play a vital role in minimizing these challenges and ensuring sustainable material cost management.

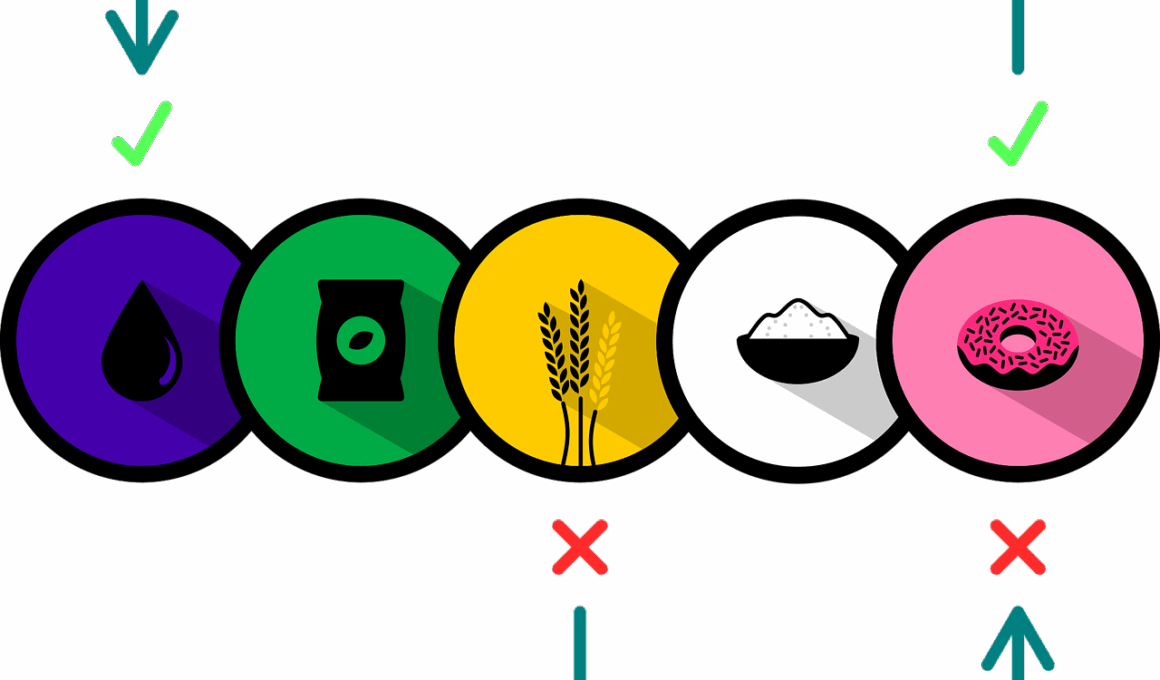

The factors influencing material costs are numerous and varied, particularly amidst supply chain disruptions. Increased transportation costs, tariffs, and fluctuating demand also exacerbate rising material expenses. When disruptions occur, companies often experience extended lead times for obtaining raw materials. For example, if a major shipping route is obstructed, costs escalate as companies seek alternative forms of transportation. Additionally, tumultuous market conditions can heighten competition among businesses for the same limited resources. This spike in competition can further inflate material prices. Another contributing factor is the unforeseen costs associated with quality control when sourcing from alternative suppliers. Many businesses lose time and money when switching suppliers. Internally, additional resources may be required to reassess supplier qualifications. This process becomes even more complicated when potential substitutes come from economically unstable regions. Consequently, the total cost of material acquisition escalates beyond just price per unit. Efficient procurement practices also suffer during these disruptions, forcing companies to reassess their entire supply chain strategy to optimize material sourcing. Incorporating predictive analytics can help businesses forecast demand and manage inventory levels more effectively. Adopting technology tools is essential for managing ongoing supply chain complexities.

Strategies for Managing Material Costs

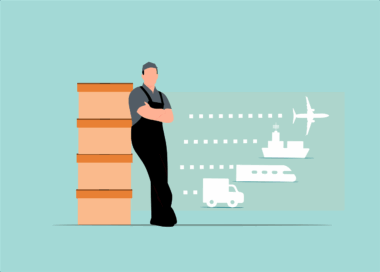

Companies adopting innovative strategies to manage material costs can mitigate the impact of supply chain disruptions. One effective approach is securing multi-supplier relationships to ensure a diversified source of materials. By avoiding over-dependence on a single supplier, businesses can buffer against disruptions that impact specific suppliers. Moreover, engaging in long-term contracts can provide stability in pricing and availability. Companies might consider negotiating fixed prices for one or two years to manage costs effectively. Another strategy involves investing in local suppliers. This not only supports local economies but also reduces reliance on international shipping, which often gets disrupted. Just-in-time (JIT) inventory methods can lead to significant cost savings by minimizing the amount of inventory on hand. However, this requires a robust supply chain capable of prompt deliveries without compromising quality. Companies should also employ technology for improved tracking and responsiveness. Digital tools such as supply chain management systems can proactively identify potential disruptions. Thus, a blended strategy combining flexibility, forecasting, supplier diversification, and technology will help to keep material costs in check.

Financial prediction plays a crucial role in managing material costs effectively during supply chain disruptions. Businesses should analyze historical data trends to forecast future material price movements better. Using statistical models based on past disruptions can aid in predicting outcomes during similar events in the future. This kind of foresight allows companies to prepare their budgets accordingly and allocate necessary resources to manage anticipated rises in material costs. Additionally, establishing financial reserves can provide a safety net during turbulent periods. Allocating funds for material purchases in advance can protect against price hikes. Working closely with financial analysts to assess cash flow needs related to material acquisition is key. These analysts can also explore options like bulk purchasing to offer savings while securing required materials in advance. Sometimes, promoting collaborative purchasing among businesses sharing similar supply chain needs can also yield discounts. Moreover, consistently measuring procurement performance against pre-determined KPIs ensures that firms remain proactive about their operational efficiency. Ultimately, integrating sound financial insights with effective procurement strategies can create a robust framework for managing costs.

The Role of Technology in Supply Chain Management

Technology has transformed supply chain management and plays a pivotal role in material cost control. Cloud-based platforms enable real-time tracking of shipments, allowing businesses to promptly respond to potential supply chain disruptions. Advanced analytics can help identify patterns, thereby improving decision-making related to material sourcing. Incorporating artificial intelligence and machine learning tools can also enhance forecasting accuracy, enabling companies to optimize inventory levels more efficiently and reduce costs. Moreover, utilizing blockchain technology improves transparency and traceability, which are crucial when assessing supplier reliability during disruptions. By ensuring the authenticity of materials, companies can enhance quality control and minimize financial losses that arise from substandard supplies. Additionally, integrating ERP systems streamlines information sharing among departments. This alignment ensures that procurement knows about upcoming sales forecasts, thus allowing for strategic material planning. These technologies not only aid in cost management but also solidify relationships across the supply chain. Organizations must invest in technological solutions that facilitate seamless communication and transparency. The goal is to create a more robust supply chain ecosystem capable of withstanding pressures directly impacting material costs.

Despite the challenges posed by supply chain disruptions, opportunities emerge for improved material costing strategies. Companies that can adapt quickly and develop resilience stand to gain a competitive advantage. Investing in personnel training programs focused on supply chain agility is essential. Understanding the complexities of material sourcing and the economic factors affecting them can lead to more informed decision-making. Building a culture that encourages flexibility and proactive problem-solving is vital for mitigating adverse effects during disruptions. Additionally, regular reviews of supplier contracts enable businesses to renegotiate terms and improve pricing based on the current market climate. Continuous engagement with suppliers fosters closer relationships, allowing for more transparent communication regarding potential issues on both sides. Furthermore, companies should explore sustainable practices in material sourcing, which can sometimes yield cost savings in different ways. Adopting methods focusing on reducing waste and improving efficiency within material acquisition processes can lead to lower overall expenses. Ultimately, companies that proactively navigate both threats and opportunities arising from supply chain disruptions stand the best chance of managing their material costs effectively.

Conclusion and Future Outlook

In conclusion, the effect of supply chain disruptions on material costs is profound and multifaceted. As industries continue to globalize, the impacts of such disruptions will likely intensify. However, adopting strategic approaches significantly aids in mitigating these effects. Emphasizing technology adoption, proactive financial management, and building resilient supply chains will empower businesses to remain competitive. Future advancements in technology are set to further revolutionize how companies manage supply chains. With growing interest in artificial intelligence, it is paramount to harness analytics tools to ensure data-informed decisions around materials. Moreover, fostering partnerships with suppliers that prioritize sustainability can lead to mutual benefits. Ultimately, organizations need to remain vigilant of economic conditions while adapting their strategies as necessary. Continuous improvement and flexibility will be key factors in successfully controlling material costs, particularly during periods of uncertainty like disruptions. Understanding these dynamics can lead to better decision-making and enhanced operational efficiency. A resilient supply chain will not only endure the challenges posed by material costs but also thrive in an increasingly dynamic market. Organizations that embrace these changes can look forward to improved stability and sustainability in their operations.

To summarize, material costing is intricately tied to a myriad of factors influenced by supply chain disruptions. Innovating and adapting to the challenges posed by these disruptions is crucial for businesses. Secure multi-supplier relationships, investing in technology, and agile management are some strategies to consider. Organizations must be proactive in their approach rather than reactive when facing potential disruptions. Continuous monitoring of market trends and economic indicators related to material sourcing can facilitate timely responses, ensuring that companies protect their bottom line. Training and development of team members in procurement processes are equally fundamental for building resilience. In a world characterized by uncertainty, organizations that can pivot effectively will find opportunities where others see obstacles. Engaging with suppliers, exploring sustainable sourcing options, and implementing advanced forecasting tools will contribute to optimizing material costs. Ultimately, companies have the potential to emerge stronger after overcoming supply chain disruptions. Development of contingency plans and regular assessments of supplier performance can also fortify operational capabilities. In a complex economy that continues to evolve, agility in material cost management will ensure long-term success.