How to Identify Vulnerabilities in the Supply Chain

Identifying vulnerabilities within a supply chain is critical for enhancing resilience and mitigating risks effectively. One of the first steps involves conducting a thorough analysis of the entire supply chain process. This analysis should encompass inputs from all stakeholders, including suppliers, manufacturers, and logistics providers. Break down the supply chain into components to identify potential weak spots. Focus on areas such as sourcing, production, transportation, and distribution. After pinpointing the individual elements, assess their reliability, stability, and potential for disruption. Use qualitative data from industry reports and quantitative analysis from past performance, to unveil patterns or signs of weakness. Additionally, develop a supply chain mapping process to visualize connections between various components. This method helps in recognizing points where there may be external pressures or interruptions. You can leverage tools like risk assessment matrices and simulations to further experiment with potential failure scenarios. This helps in prioritizing risks and planning accordingly, ensuring that action can be taken to reduce vulnerabilities. Moreover, engaging with supply chain software solutions can streamline the risk assessment process significantly.

Another crucial aspect of identifying vulnerabilities is performing regular stress testing. Stress testing provides insights into how well the supply chain performs under extreme conditions, such as natural disasters, political unrest, or pandemics. By simulating these scenarios, businesses can determine the robustness of their supply chain and understand where bottlenecks may occur. Implement scenario analysis to evaluate the likelihood and consequences of various risk events. Create qualitative assessments alongside quantitative metrics to ensure a comprehensive evaluation. Collaborating with expert consultants can further bolster this process, bringing in outside perspectives and experience that enhance the analysis. Documentation plays a key role, so ensure that records reflect the current state of vulnerabilities up to date, integrating new findings or past experiences into the analysis. Additionally, it is essential to communicate findings with all members of the organization. Share the knowledge gathered from testing and analysis, which serves to cultivate a proactive risk management culture. Encourage cross-functional teams to contribute insights and join forces toward creating contingency plans. This collaboration can yield creative problem-solving strategies, ultimately enhancing the supply chain’s resilience.

Utilizing Technology for Vulnerability Assessment

In the modern age, technology serves as a powerful ally in identifying supply chain vulnerabilities. Advanced analytics and big data tools can help uncover hidden patterns that are not easily visible through traditional methods. These technologies assess complicated data sets, providing actionable insights about risks across the supply chain. Implementing predictive analytics allows organizations to foresee potential disruptions and devise response strategies. Real-time monitoring and data collection can further empower businesses to spot signs of potential issues immediately. For instance, employing Internet of Things (IoT) devices can facilitate real-time visibility into the supply chain’s condition. By gathering metrics regarding inventory levels, shipping status, and supplier performance, organizations can improve decision-making through timely alerts on discrepancies. Additionally, artificial intelligence and machine learning algorithms can analyze historical data, enhancing the capacity for risk prediction and management. This continuous learning cycle makes the supply chain more adaptive to unforeseen challenges. Companies looking to become more proactive should invest in these technologies, creating a competitive edge. Ultimately, leveraging new technologies expedites the identification of vulnerabilities, aligning with overall business strategy.

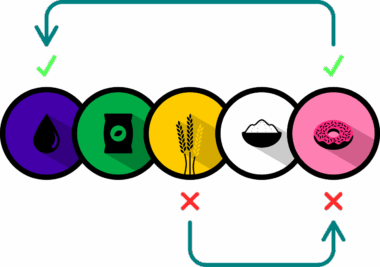

Supplier evaluation and management is also key to safeguarding the supply chain. Regularly assessing suppliers for their stability, compliance, and performance is vital. This can be achieved through vendor audits, supplier scorecards, and performance metrics. Establishing metrics for evaluation provides a solid framework, enabling decision-makers to gauge supplier reliability consistently. Create a robust criterion that includes evaluating financial health, production capacity, quality standards, and adherence to regulations. Additionally, implement continuous improvement measures to develop dynamic relationships with suppliers. Open communication channels are essential; maintain frequent discussions to discuss potential risks. Supplier diversification is another strategy to fortify supply chain resilience. By avoiding over-reliance on a single supplier, businesses can safeguard themselves against disruptions originating from that source. Engage in collaborative partnerships and risk-sharing initiatives with key suppliers to solidify their role as part of a unified supply chain strategy. Furthermore, developing contingency plans specific to each supplier can help mitigate impacts in case of supplier failure. These strategies together create a framework for identifying vulnerabilities while reinforcing overall supply chain stability.

Risk Culture and Awareness

A strong risk culture within an organization is instrumental in identifying supply chain vulnerabilities. Organizations need to foster an environment where risk awareness is prioritized. Encourage all employees to be vigilant and report potential issues without fear of retaliation. This cultural shift can lead to faster identification of vulnerabilities as foot soldiers gather insights. Training sessions and workshops should be conducted regularly to educate staff on risk management principles. Moreover, establishing risk committees can further enhance the focus on vulnerability assessment. These committees should comprise cross-sectional representatives to encompass diverse viewpoints. Consider implementing a platform for monitoring risks where feedback from various teams can be collected and analyzed. This creates an open dialogue about vulnerabilities, ensuring that concerns are addressed promptly. Moreover, ensuring executive buy-in is essential for an effective risk culture. Leadership must emphasize the importance of supply chain risk management across the organization. Collaborate with their support to allocate needed resources. Consequently, a unified approach towards risk management helps organizations adapt proactively to the evolving nature of supply chain vulnerabilities, reducing potential fallout.

Continuous improvement and feedback mechanisms are essential components for sustaining vulnerability identification in supply chains. After identifying vulnerabilities, businesses must develop methods to learn from past incidents. Establish routines for reviewing incidents to extract lessons and refine strategies. Use a structured approach such as Plan-Do-Check-Act (PDCA) to embed improvement protocols into existing frameworks. Ensure that employees feel encouraged to suggest enhancements based on their insights. Implementing these suggestions often fosters a more agile supply chain capable of adapting to ongoing changes. Additionally, leveraging customer feedback can also yield valuable perspectives on potential vulnerabilities. Customers can provide insights into logistical lead times, product quality concerns, or unexpected delays, making them important stakeholders. Surveys and feedback requests can help collect necessary information. Adopt an agile mindset towards innovation, continually exploring better systems, processes, and technologies that facilitate vulnerability management. As the landscape changes, businesses must align their supply chain processes with industry advancements. Encourage a culture of curiosity and experimentation to drive continuous learning. Making iterative improvements to risk management practices ensures that vulnerabilities are promptly addressed, maintaining supply chain integrity.

The Role of Collaboration in Mitigating Risks

Collaboration among supply chain partners is paramount in identifying vulnerabilities and managing risks effectively. Establishing clear expectations and communication channels with suppliers creates a strong foundation for fruitful relationships. Holding collaborative workshops or training sessions can foster a network where partners share best practices. This ensures that all stakeholders understand their role in addressing vulnerabilities. Encourage sharing knowledge and insights through these platforms, fostering a greater understanding of collective risks. Establish joint contingency plans with partners that outline the necessary response during disruptions. By pooling resources, organizations gain access to combined expertise, helping them navigate potential challenges effectively. Share data credibility among partners to build trust and transparency; this strengthens collaboration efforts. Investing in joint technology solutions can further streamline information sharing and risk assessment processes. Moreover, such collaborations can mitigate potential compliance risks by keeping all partners up to date on changing regulations and standards. By working together, companies can build relationships that enhance overall resilience, enabling them to respond decisively to vulnerabilities. In conclusion, partnerships play a vital role in identifying and addressing supply chain vulnerabilities proactively.

In summary, identifying vulnerabilities in the supply chain necessitates a comprehensive approach involving continuous assessment, advanced technology, strong culture, and collaboration. It is an ongoing process that requires dedication and strategic planning across various organizational levels. Regularly reviewing and updating risk management practices is essential as market dynamics evolve constantly. Amidst the perils that businesses face, being equipped with sound risk management strategies paves the path toward long-term sustainability. Organizations thrive when they remain proactive and vigilant, prepared to address any disruptions that may arise. Embracing a holistic view of the supply chain allows leaders to optimize performance and safeguard their operations. Make sure that every team member knows their role in risk management so they can contribute effectively. This collective approach means risks are identified and addressed swiftly, minimizing negative effects. Lastly, organizations should remain agile and open to change, responding promptly to market shifts or emerging threats. By combining insights from data analytics, stakeholder feedback, and industry best practices, firms can develop robust frameworks to identify vulnerabilities. Moving forward, sustained commitment to these efforts will distinguish successful supply chains from those that struggle.