The Role of Inventory Management in Material Costing

Effective inventory management is crucial in the realm of material costing and control. It involves tracking goods from manufacturers to warehouses and ultimately to the point of sale. Inventory management helps businesses track material costs accurately, ensuring that they maintain sufficient stock levels without overstocking. Implementing robust inventory management systems can reduce wastage and ensure that materials are available when required. This is particularly important in industries where timely availability of materials directly affects production schedules and overall operational efficiency. Without precise inventory management, companies may find themselves facing stockouts, which can lead to production delays and decreased customer satisfaction. Moreover, excess inventory can tie up capital unnecessarily and increase holding costs, which can strain financial resources. An effective approach to inventory management also encompasses techniques such as just-in-time (JIT) inventory and demand forecasting. Businesses can adapt their inventory strategies based on historical data and consumer demand, ensuring a balanced flow of goods throughout the supply chain. Consequently, mastering inventory management is indispensable for organizations aiming to optimize their material costing efforts effectively.

Another important aspect of inventory management is its impact on financial reporting. Accurate tracking of inventory allows businesses to present a clearer financial picture. This is critical for compliance with financial regulations and ensuring investor confidence. Material costs often form a significant portion of the overall costs in manufacturing. Therefore, accounting for these costs accurately directly influences profitability. Companies typically utilize various inventory accounting methods, such as FIFO (First In, First Out) or LIFO (Last In, First Out), to determine the cost of goods sold. These methods reflect how inventory is managed and ultimately influence reported earnings. An effective inventory management program can also help identify trends and fluctuations in costs, allowing for more informed decision-making regarding pricing strategies and sourcing materials. Furthermore, inventory systems can streamline operations by integrating with other business functions, providing a more holistic view of financial health. As a result, firms can make strategic decisions based on comprehensive data that takes into account all aspects of material costs and controls. This synergy between inventory management and financial reporting is vital for achieving long-term operational and financial success.

Strategies for Effective Inventory Control

Implementing effective inventory control strategies is vital to manage material costs and ensure operational efficiency. One successful strategy is adopting an automated inventory management system that integrates with other business processes. Such systems can help track stock levels in real-time, alert management of reorder points, and reduce manual errors associated with inventory tracking. With advancements in technology, businesses can also leverage RFID (Radio Frequency Identification) and barcode scanning to enhance accuracy and efficiency in inventory counts. Regular audits and cycle counts of inventory are crucial practices to ensure that recorded inventory aligns with physical stock. This alignment helps prevent discrepancies that could adversely affect cost calculations. Another effective strategy is establishing strong supplier relationships, enabling businesses to negotiate better pricing and terms. Additionally, businesses might consider implementing inventory KPIs (Key Performance Indicators) such as inventory turnover ratio, which measures how quickly inventory is sold and replaced. By analyzing these metrics, firms can optimize stock levels and minimize costs. Furthermore, properly training staff in inventory management processes fosters accountability and improves overall performance in maintaining optimal material levels and reducing waste.

Inventory turnover is a critical metric that reflects how efficiently a company utilizes its available stock. A high turnover rate indicates robust sales and effective inventory management, whereas a low rate may suggest overstock issues, potential obsolescence, or poor sales. Businesses can leverage turnover data to evaluate their purchasing strategies and adjust their material ordering accordingly. Understanding seasonal trends and market shifts can further optimize inventory levels. For example, companies might increase inventory during peak seasons to meet heightened demand while minimizing stock during off-peak periods. Implementing demand forecasting techniques allows businesses to anticipate changes in the marketplace and adjust their inventory accordingly. Utilizing historical sales data, industry reports, and economic trends provides valuable information for effective decision-making. This approach not only aids in controlling costs but also enhances customer satisfaction by ensuring that products are available when required. Such proactive planning and strategic inventory control translate to better financial outcomes and strengthened customer loyalty. As businesses navigate the complexities of the market, integrating turnover insights into their inventory management practices can provide a competitive edge in ensuring material availability.

The Relationship Between Inventory Management and Cost Control

The relationship between inventory management and cost control cannot be understated in today’s competitive business landscape. Efficient inventory management contributes significantly to minimizing costs associated with holding, ordering, and stockout. By controlling inventory levels effectively, businesses reduce their cash conversion cycle, resulting in improved liquidity and financial health. Properly managing inventory can help alleviate excess carrying costs, such as warehousing expenses and insurance. Costly overtime and expedited shipping resulting from stockouts can also be reduced with proactive inventory management practices. Companies can enhance their cost control by utilizing analytical tools that evaluate their inventory needs and optimize procurement processes. By analyzing historical data, businesses can reduce waste and improve their order quantities. Furthermore, engaging suppliers in collaborative planning can streamline inventory control, resulting in cost savings and enhanced supply chain efficiency. Cost control measures can also benefit from leveraging advanced technologies such as AI for predictive analytics. This approach assists organizations in forecasting demand accurately and ensuring that the right amount of material is on hand at any given time. Ultimately, effective inventory management forms the backbone of cost control efforts across various sectors, boosting profitability.

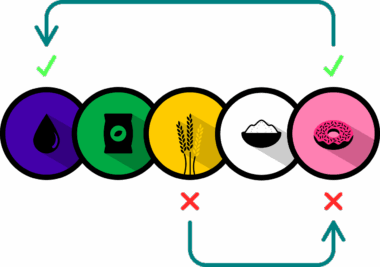

Material costing is inherently linked to the principles of inventory management and control. Organizations utilize precise costing methods to ensure accurate valuation and reporting of materials. Material cost accuracy is vital for financial reporting as it affects the overall cost of goods sold. Understanding the flow of materials through inventory systems helps businesses adopt appropriate costing methodologies. For instance, companies may choose between standard costing, based on average costs, or actual costing, which accounts for real-time pricing fluctuations. Besides, an efficient inventory system allows businesses to track variations in material costs, which is essential for price adjustments and budget forecasting. When material costs are controlled meticulously, businesses can set competitive pricing that adheres to market conditions. Furthermore, understanding variances between expected and actual costs enables organizations to implement corrective actions swiftly when discrepancies arise. This capacity to analyze and respond to material cost changes solidifies inventory management’s role in effective financial performance. Consequently, a comprehensive approach toward material costing and inventory management fosters an organization’s ability to thrive amidst ever-evolving market dynamics.

Conclusion

In conclusion, effective inventory management is a cornerstone of successful material costing and control. Companies that invest in robust inventory systems realize the benefits of cost savings, improved financial reporting, and enhanced operational efficiency. Accurate tracking of inventory not only aids in meeting production needs but also informs crucial financial decisions. Businesses that employ automated systems and data-driven strategies to manage inventory enjoy the advantages of reduced waste and streamlined processes. Additionally, organizations fostering strong supplier relationships can negotiate better terms and enhance their material flow. Understanding the interplay between inventory turnover and material costs enables businesses to adjust their strategies accordingly. As market demands continuously shift, the importance of proactive inventory management becomes increasingly apparent. Firms that leverage advanced technologies and adhere to best practices in inventory control position themselves favorably in their industries. Therefore, effectively managing inventory is not merely an operational necessity; it is a strategic imperative for achieving sustainable growth and profitability. In the competitive landscape, success hinges on the ability to manage materials efficiently while controlling costs effectively.

Additionally, it is worth noting that continuous improvement is essential within inventory management. Organizations should always look for ways to optimize their processes and reduce costs. Regularly assessing inventory performance through various metrics, such as accuracy and turnover ratios, can help firms identify areas for enhancement. Training employees on current best practices and utilizing new technologies can also yield significant benefits. Furthermore, incorporating sustainability into inventory practices is becoming increasingly important. Companies are now focusing on reducing their carbon footprint and minimizing waste associated with excess inventory. This can involve initiatives such as recycling unused materials or sourcing from sustainable suppliers. In summary, the relationship between inventory management and material costing is a multifaceted and evolving domain. As businesses strive for excellence, those that commit to implementing effective inventory management practices will find themselves better equipped to navigate the complexities of material costing. By fostering a culture of continuous improvement and sustainability, companies can enhance their competitive edge and ensure long-term success in today’s market dynamics.